An efficient strapping machine in India keeps your operation going fast, consistent, and neat. Different factories have different volumes and product sorts.

A proper strapping machine cuts down on time, errors, and product wastage.

The demand is increasing in sectors such as FMCG, textiles, printing, e-commerce, and logistics; therefore, factories in India cannot afford to have packaging systems that can’t keep pace with production.

The right strapping machine provides you with uniform strapping, safeguards your shipments, and significantly reduces your packaging costs.

This guide by Prime Packed simplifies the decision process into manageable steps so that you can select the best option for your production line.

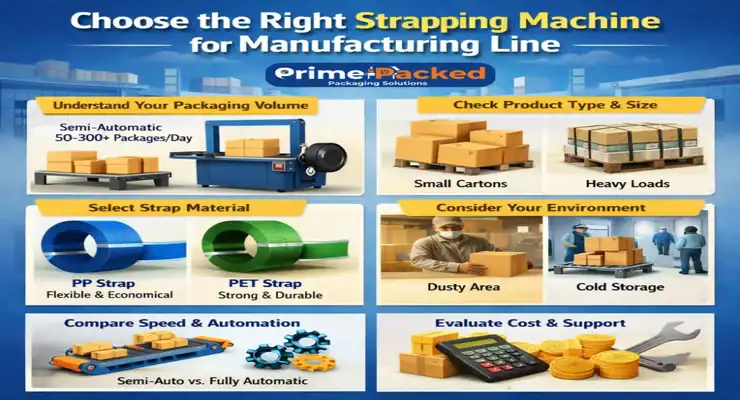

Step 1: Understand Your Packaging Volume

To begin with, find out the number of packages you are shipping daily. If your daily package count is between 50 to 300, a semi-automatic machine might be a perfect fit for you and it will also save you from making an unnecessary investment.

When the range of packages increases to 300 to 800, then automatic machines become more feasible as they reduce the need for the operator and speed up the process.

High-volume factories that use conveyors or have several stations operating need arch-type automatic systems that are capable of running non-stop at full output.

Selecting according to volume makes sure that your machine is not over-stressed or under-utilised.

Step 2: Check the Type and Size of Products You Strap

The shape and weight of your product are crucial in this matter.

Cartons and FMCG packs are easily processed on tabletop machines.

The heavier bundles like metal parts, tiles, books, and textile rolls, need more powerful machines that can apply higher tension.

Pallets and large boxes usually require side-seal machines because the sealing head is kept away from dust and debris.

If your products are small or of an irregular shape, search for machines with narrow arches and stable strap-feeding to avoid jams. Proper pairing of the machine and the product eliminates feeding problems and prevents loose straps.

Step 3: Select the Strap Material You Need

PP Strap

PP straps are flexible, economical, and widely used for packaging cartons, printing, and light manufacturing.

They meet every day use in packaging and work perfectly with both semi-automatic and automatic strapping machines.

For companies seeking to control production in-house, a pp strap making machine in India helps to lower material costs and provides better control over the supply chain.

PET Strap

PET straps are the strongest, the most durable, and the most suitable for heavy industrial loads such as appliances, tiles, plywood, metals, and bricks.

They will not stretch and will provide a reliable tension throughout the shipment journey.

Industrial sectors that experience rough handling can benefit from installing a pet strap manufacturing machine in India to have quality control and save on outsourcing costs.

Step 4: Consider the Working Environment

Environmental conditions in the factory affect the quality of machines. Dusty conditions that include plywood, chemical or textile manufacturing will require side-seal machines that are properly sealed.

The clean and dry areas are alright for standard top-seal models. Low-temperature heater recovery machines are required in cold storage units.

In case your packaging area is wet or is affected by chemicals, opt for a machine that is constructed using materials which can resist corrosion.

When your machine becomes perfect for the environment you are in, then the breakdowns will be less frequent and the machine life will be extended.

Step 5: Compare Speed and Automation Levels

As the number of items increases, speed becomes a crucial factor.

Semi-automatic devices provide about 20 to 30 straps per minute, which is appropriate for moderate daily capacities.

The automatic ones can deliver 40 to 60 straps per minute and lessen the participation of the operator.

Moreover, fully automatic inline systems can provide even higher speeds as they work directly with conveyors.

An automatic strapping Machine manufacturer in India will provide you not only the speed but also the long-term support.

Step 6: Confirm the Maintenance Requirements and the Resize Parts in Stock

The maintenance of the machines is the one that will decide whether the production line runs continuously or not.

Think about how often machines need servicing, cleaning, and adjustments. Moreover, the supplier must ensure that access to critical spare parts such as heaters, knives, rollers, motors, and control boards is extremely fast.

The machines with parts that are easily available have a shorter downtime and thus no loss of production.

A seller with a skilled service team and local stock always provides better long-term value.

Step 7: Compare Total Cost, Not Just Price

A low upfront price frequently appears to be a great option at first; however, it may subsequently result in higher operating costs.

The analysis should take into account the daily power consumption of the device, the number of straps it throws away, spare parts cost, repair rate and the effect of downtime on your team’s productivity.

A powerful and solid strapping machine will be more costly at the initial stage but it will be globally rewarding in terms of real savings and effort after several years.

Step 8: Evaluate Safety and User-Friendliness

The presence of a clear button, smooth feeding of straps, adjustable tension, and an emergency stop that is easy to operate significantly enhances the simplicity of the strapping machine.

A user-friendly design lowers training time, fatigue, and keeps your packaging area running smoothly all day long. In busy lines, a strapping machine that is easy to comprehend instantly raises confidence and output.

Step 9: Choose a Reliable Supplier in India

If you are already fed up with malfunctions, waiting and suppliers who disappear after installation, then Prime Packed is the one who will support your line.

Let’s create a packaging system that will keep you company without trouble every day. Contact and improve your operations today.

Frequently Asked Questions

1. Which strapping machine should I choose for my factory?

Your daily packaging volume, product dimensions, and automation requirements are the factors that determine your selection.

2. Is installation and after-sales support included in your service?

Yes, indeed. Prime Packed not only installs the equipment but also provides training and continuous service support for a smooth operation.

3. Is the availability of spare parts in India an easy affair?

Definitely. We have an uncommitted stock of important spare parts to cut down on downtime and prevent prolonged service.

4. Is it possible for you to assist in switching from manual or semi-automatic strapping to automatic?

Surely. We will support you in the transition to automatic systems while keeping your current production line running.